2.8 Spindle

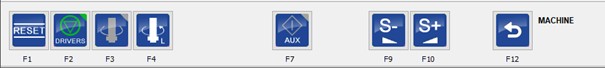

The F7 "MACHINE" button takes you to the following menu:

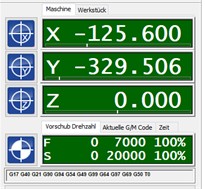

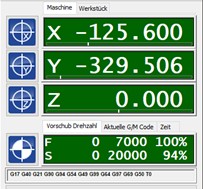

As in the main view, the suction and the spindle motor can be switched on and off here. In addition, the spindle rotation speed can be changed using the F9 and F10 buttons, each Click +/- 1%. The value is displayed as a percentage in the main view below the position information:

Installation/uninstallation of the CNC software from EDING

- Installation from USB stick via Setup.exe

- IMPORTANT: After installation, start the software before the parameters are copied!

- Exit the programme!

- Now copy the parameters manually into the root directory of the software.

- To uninstall, exit the programme and run unins000.exe in the root directory. Delete the programme folder manually after uninstalling.

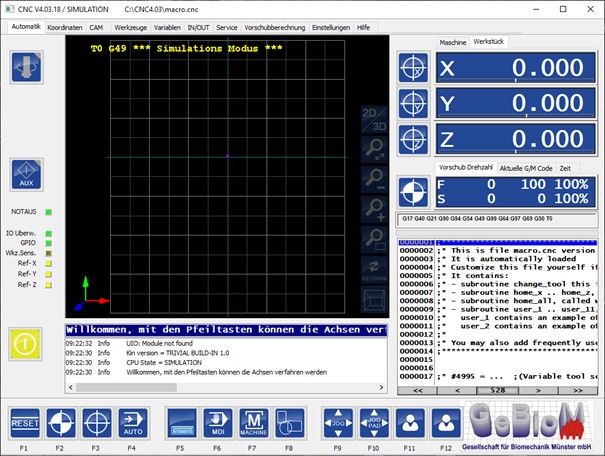

Simulation mode:

If the software goes into simulation mode after starting, it is very likely that the software was not terminated correctly, e.g. in the event of a system crash or by switching off the computer while the programme was still running. In these cases, incorrect configuration files can occur, which in turn means that the software only starts in simulation mode. The original files can be restored from the USB stick supplied. You will find them in the "Customer parameters" folder.

The software must be closed before restoring! We recommend creating a backup of the software in its current state before making any changes.

Copy the files from the Customer parameters folder on the USB stick to the root directory of the control software. The directory can usually be found on the drive C:\: C:\CNC4.03, or similar.

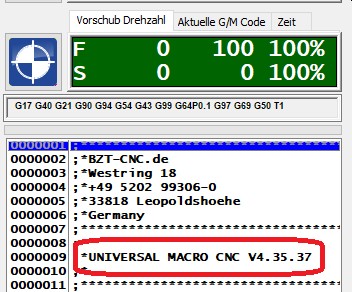

The machine should now restart in the correct mode. The correct software version will then also be displayed in the software:

Defective configuration files can be responsible for a variety of errors that manifest themselves in different reactions/unexpected behaviour of the machine, e.g. if one of the axes no longer stops during the reference run according to the display, but appears to move towards infinity.

Configuration of the network interface for communication with the control unit:

A network adapter must be assigned a fixed IP (IPV4) on the control computer:

IP: 172.22.2.120

Subnet: 255.255.255.0

All other protocols should be deactivated for this network adapter!

After installing VPN software, it is possible that an additional protocol is active on the network adapters that prevents the connection to the control unit. These protocols must be subsequently deactivated!

The network adapter on the control unit has the following IP:

IP: 172.22.2.100

Subnet: 255.255.255.0