2.9 Setting the zero point

After changing the milling cutter, the zero point of the milling cutter must be redetermined!

To do this, move the spindle motor to the centre of the vacuum table using the "Manual movement" dialogue (see page 8). The rubber mat must be on the table. Use the arrows to move the

Move down the z-axis until the tip of the cutter almost touches the rubber mat. Now place a piece of paper under the cutter and move the z-axis further down until the tip scratches the paper but the paper can still be moved easily.

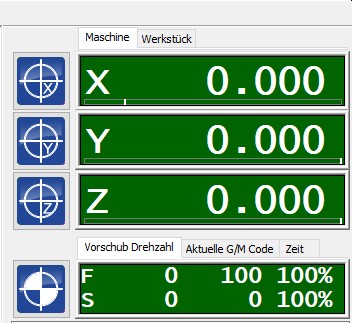

Make a note of the value that is displayed for Z in the coordinates. Make sure that the "Machine" tab is displayed, the coordinates are then highlighted in green. The coordinates in the "Workpiece" tab are highlighted in blue and must not be used!

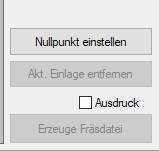

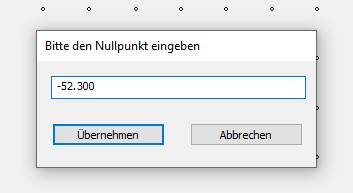

Once you have determined the zero point, switch to the GP Manager. The value is entered in the GP InsoleFraese module. To do this, hold down the CTRL key on the keyboard and click on the "Set zero point" button.

Click "Apply" to save the new zero point in the GpManager. Now create milling files with the new zero point. Old milling files that still exist must no longer be milled!