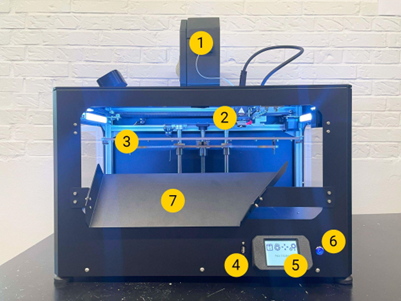

A camera is used to automatically start a print, which checks whether the object has been correctly removed from the printer and ensures that the print bed is free for the next print. Carry out the following steps to install this camera.

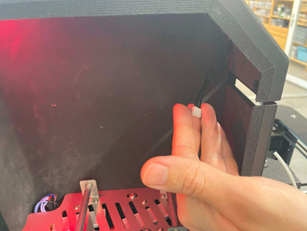

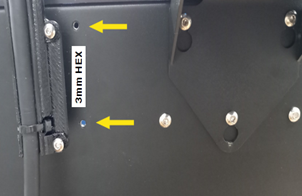

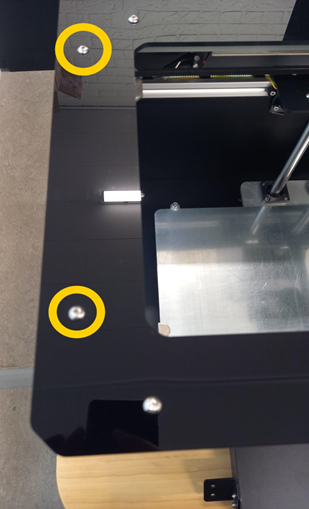

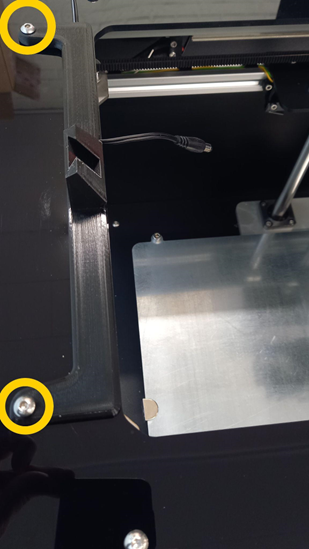

| 1 | Remove the 2 screws located on the left side of the top printer frame. |  |

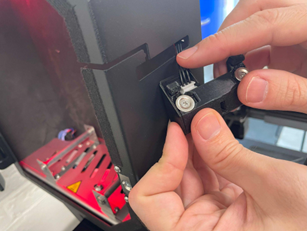

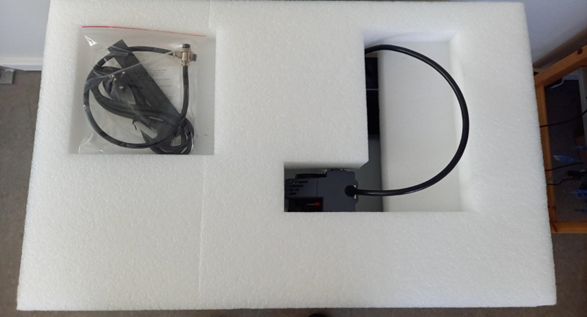

| 2 | Take the camera mount and the power supply unit. Place the power supply cable in the channel of the holder so that the power socket protrudes 6-7 cm. |  |

| 3 | Place the bracket on the left side of the upper printer frame, align the bracket with the holes of the removed screws and reinsert the fixing screws. When properly installed, the camera's power supply cable is concealed under the bracket. |  |

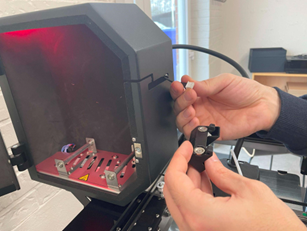

| 4 | Position the camera in the recess provided in the holder. |  |

| 5 | Connect the power cable to the camera. |  |