This manual contains safety warnings and instructions that apply to the 3D printer, model "Mike" apply.

The following signs are used with the safety instructions.

Information that is helpful for carrying out an action or avoiding security problems.

Information that is helpful for carrying out an action or avoiding security problems.

General warning sign: Warning of a potentially dangerous situation if the safety instructions are not followed (ISO 7010-W001)

General warning sign: Warning of a potentially dangerous situation if the safety instructions are not followed (ISO 7010-W001)

Magnetic field warning (ISO 7010-W006)

Magnetic field warning (ISO 7010-W006)

Warning of electrical voltage (ISO 7010-W012)

Warning of electrical voltage (ISO 7010-W012)

Warning of hot surface (ISO 7010-W017)

Warning of hot surface (ISO 7010-W017)

Warning of hand injuries (ISO 7010-W024)

Warning of hand injuries (ISO 7010-W024)

The 3D printer Mike may only be used after reading the safety instructions and the operating instructions.

Do not use the interior/chamber of the printer for any kind of storage.

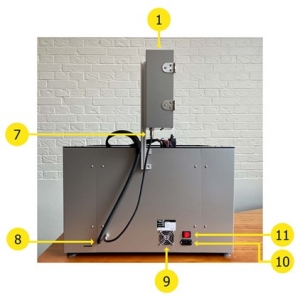

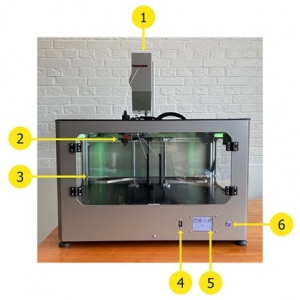

Control the 3D printer Mike always via the touchscreen on the front and/or the power switch on the back.

Do not use any material other than the compatible filament Addigy® FPU 79AR8 of the company Covestro into the print head.

Keep the front/door of the printer closed while the machine is in operating mode. Never reach into the machine during the printing process.

The main chamber of the machine (print chamber) has a backlight that indicates the machine status. The safe states for opening the front/door and entering the chamber are "Paused", "Idle" and "Print done", which are signalled by a steady or flashing green light.

All other light colours show "operating modes" in which the chamber must be closed. Further details on backlighting can be found in the operating manual in chapter 5.3.

Do not reach into the print area from the top of the printer. Only use the intended front side/door when removing the print object for cleaning and maintenance purposes.

Do not touch the nozzle/print head when reaching into the print area to remove the printed product. Nozzle parts become hot during printing.

Do not change any spare parts while the machine is in operating mode, unless expressly stated otherwise for maintenance or service reasons.

Always change the filament using the control panel (touchscreen) by following the standard procedure.

The 3D printer Mike is not intended for use by persons with reduced physical and/or mental capabilities or lack of experience and knowledge, unless they are supervised or have received instructions on the use of the appliance from a person responsible for their safety.

Children should never use the machine unsupervised.

When moving the machine, always lift it from below. Do not lift the machine from the side. There is a high risk of damaging the functional structure of the printer. Information on unpacking the machine can be found in the instructions in the Quick Start Guide and in the operating manual in chapter 4 Preparing the printer.

There is a potential risk of burns as the nozzle/print head can reach temperatures in excess of 200°C. Do not touch the nozzle with bare hands.

There is a potential risk of burns as the nozzle/print head can reach temperatures in excess of 200°C. Do not touch the nozzle with bare hands. The 3D printer Mike contains moving parts. The force of the print bed is great enough to cause damage, so stay away from the print bed during operation.

The 3D printer Mike contains moving parts. The force of the print bed is great enough to cause damage, so stay away from the print bed during operation. Always unplug the appliance before carrying out cleaning or service work, unless otherwise specified.

Always unplug the appliance before carrying out cleaning or service work, unless otherwise specified. The power supply unit should not be tampered with. If it needs to be replaced due to a malfunction, it must only be replaced with the same type of power supply by authorised personnel.

The power supply unit should not be tampered with. If it needs to be replaced due to a malfunction, it must only be replaced with the same type of power supply by authorised personnel. Information that is helpful for carrying out an action or avoiding security problems.

Information that is helpful for carrying out an action or avoiding security problems. Magnetic field warning (ISO 7010-W006)

Magnetic field warning (ISO 7010-W006)