You can zoom the last or trial shoe on the work surface using the following key combination:

Zoom key combination

Mouse scroll wheel smaller/greater (pointer must be in active window)

You can zoom the last or trial shoe on the work surface using the following key combination:

Zoom key combination

Mouse scroll wheel smaller/greater (pointer must be in active window)

To view the last or trial shoe from any perspective, click in the workspace and rotate it with the mouse. The direction of rotation is determined by the following key combination and mouse movement:

Key combination Mouse movement Rotation

SHIFT key +left mouse button rotate all directions freely around all axes

Press the "L, R, O, U, V, H" buttons in the function box to return to the standard views.

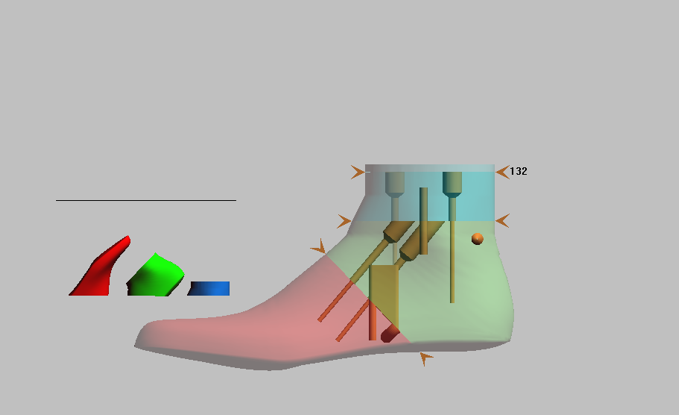

When the moulding is rotated, it loses its transparency so that you can no longer see the connecting elements within the moulding. By turning the moulding, however, you can judge where a connecting element is still protruding from the moulding.

To place the last or trial shoe anywhere on the work surface, use the following key combinations and mouse movements:

Key combination Mouse movement in the direction of the bar

CTRL key + left mouse button horizontal right or left

CTRL key + left mouse button vertically up or down

By clicking on the order in the order list, the last or trial shoe is displayed in the workspace.

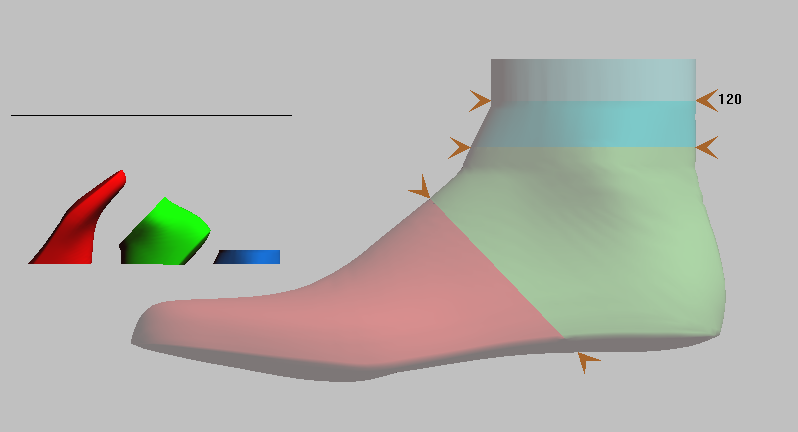

If the print job for a test shoe is selected, the following view is displayed:

The test shoe is divided into three parts for the printing process: Toe (red), heel (green) and leg (blue). The entire trial shoe is shown on the right-hand side. The orange triangles mark the cutting lines where the trial shoe is divided. The cuts can be moved by clicking on one of the triangles. In the leg area, the height (in mm) at which the height of the trial shoe is cut off is displayed on the cutting line.

On the left-hand side, the individual test shoe parts are displayed as they are positioned on the print bed. The black line above the parts indicates the maximum print height of the printer.

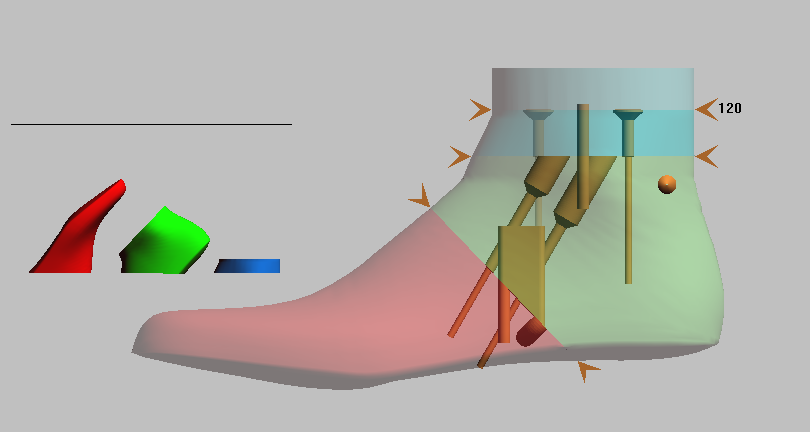

If the print job for a moulding is selected, the following view is displayed:

The last is also divided into three parts as standard: Toe (red), heel (green) and leg (blue). When the last print job is called up, the individual elements of the last are displayed on the left-hand side as they are positioned on the print bed.

The entire moulding is also shown on the right-hand side. In addition to the cutting lines, connecting elements are also drawn in so that the moulding parts can be joined together. These must also be positioned. The description of the individual elements and the special features of positioning are described in more detail in chapter 4.

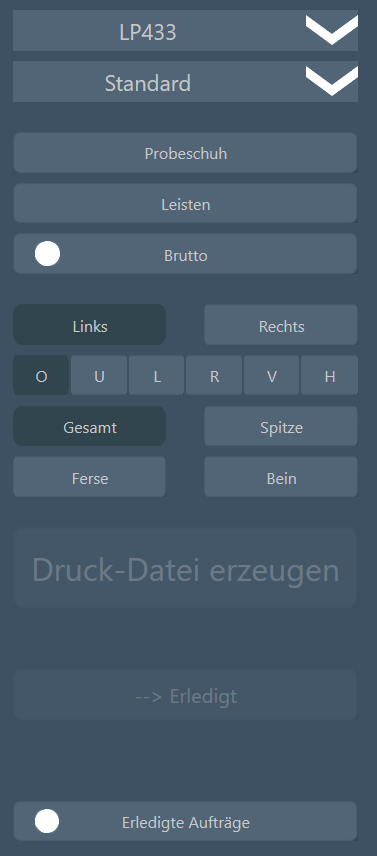

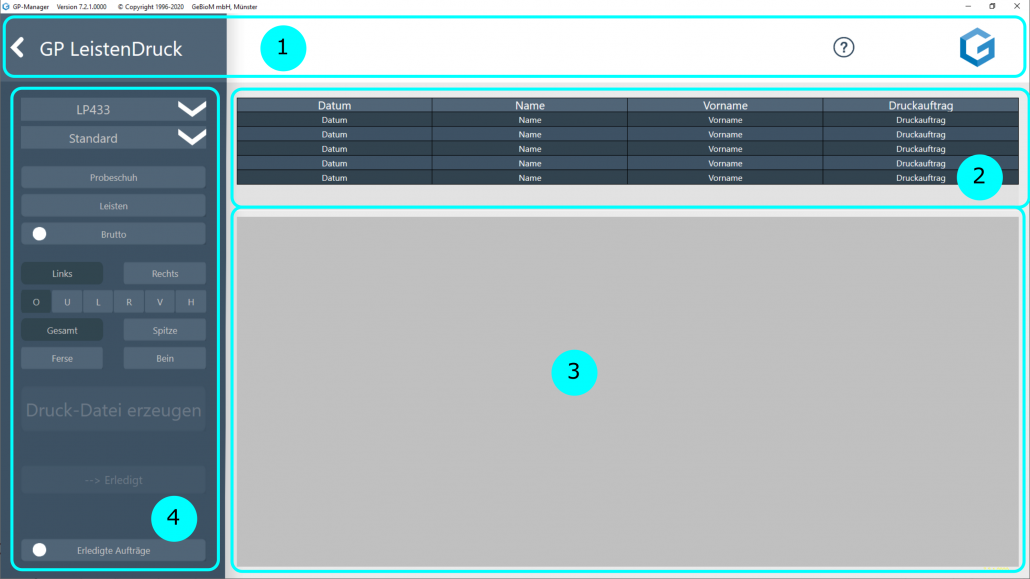

The function bar is located on the left-hand side. From top to bottom, you can first select the printer used, choose between different combinations of connecting elements, switch between views and create the print file.

The exact handling of the individual functions is explained in the next section.

The lasts or trial shoes are displayed and processed in the workspace.

Once you have selected a print job, it is displayed in the workspace. In the job list, the date the job was created, the customer's first name and surname and the print job are displayed from left to right. The active job is highlighted in blue.

In the workspace, you have the option of editing the cut and the connecting elements.

The job list displays all print jobs that were created in the GP CAD module. From left to right, the list shows you the date the job was created, the customer's surname and first name and the type of print job (last or trial shoe). Click on the order to select it and display it in the workspace.

By clicking on one of the column headings, you can sort the list according to the selected column. By default, the list is sorted by the time the job was created, with the oldest print job at the top of the list and the newest print job at the bottom.

To move the list up and down, click once in the list with the left mouse button and move the mouse up or down while holding down the mouse button.

By ticking the "Completed jobs" box, all completed print jobs are displayed.

To open the GP moulding printing module, click on the "GP moulding printing" icon in the module overview. You do not need to have selected a customer for this.

The module interface consists of the menu bar (1), the order list (2), the workspace (3) and the function bar (4).

If you have not selected a customer after starting the GP Manager, the following will be displayed in the menu bar:

The arrow (1) takes you back to the module overview. If you have problems or questions about the GP Manager, you can click on the question mark (2). This will take you directly to our support homepage.

With the GP moulding printing module, you prepare your designed mouldings for the printing process. The lasts you have created on the basis of a measurement are transferred to the GP last printing module as a print job. In the GP last printing module, you have the option of changing the pitch of the last or trial shoe and defining and positioning the connecting elements of the last. The generated data is then sent directly to the printer or optimised for the printing process using the "Simplify3D" program. The lasts or trial shoes are then printed by the printer.