The filament is no longer being conveyed or has been torn off.

Error description

The printer is not feeding any more filament or the filament has torn off.

Cause of error

The error can occur if the filament has broken inside the print head or has become stuck in the print head.

Troubleshooting

Tools required

- 1 x 7 mm open-end/lever spanner

- 1 x 16 mm open-end/lever spanner

- 1 x 2 mm Allen key

- Scissors or cutter knife

- Thermally conductive paste

- Cable ties (optional)

- Pointed pliers (optional)

- Gloves (optional)

- Heat gun (optional)

Removing the hotend from the print head

- Heat the hot end to the maximum temperature (285° - 290 °C).

It is essential to adhere to this! Otherwise the thermal barrier (heatbreak) may break! - Loosen the feed jaws and pull the filament out of the print head if necessary.

- Loosen the nozzle (open-end spanner 7 mm / 16 mm).

- Allow the printer to cool down and remove the nozzle. If the nozzle cannot be removed, heat the printer up again (285° - 290 °C) and unscrew the nozzle further.

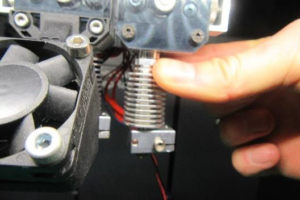

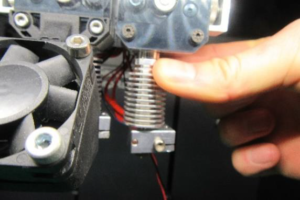

- Loosen the lower clamping screws with a 2 mm Allen key

- Disconnect all plug connections of the hotend to the wiring harness (remove the cable ties if necessary)

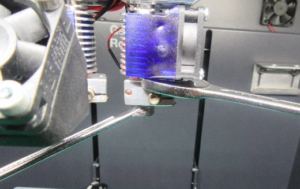

- Pull the hotend out downwards (turn if necessary).

- Disassemble the hotend

If the parts are very dirty due to leaking filament, you can heat the parts with a heat gun and remove the soft filament.

Mounting the hotend

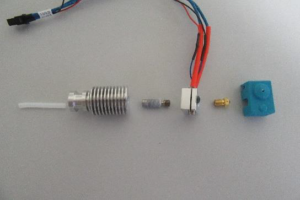

- Apply thermal paste to the long threaded side of the thermal barrier.

This step is important, as otherwise the filament will heat up in the heat sink and lead to a clogged hotend!

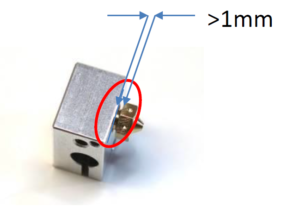

- Screw the thermal barrier into the heating block until the thread is flush with the heating block.

- Screw in the nozzle by hand from the other side.

There should be a gap of approx. 1 mm between the nozzle and the heating block. If not, unscrew the thermal barrier slightly.

Nozzle in heating block with small gap

- TPU 93 is a very soft material that tends to bend sideways between the filament screw and Bowden. This leads to filament jams and pressure dropouts. The following solution helps to optimally guide the TPU.

Cut a piece of Teflon bowden with OD 4 mm / ID 2 mm approx. 45 mm long. Cut one end into a V-shape. This allows the hotend bowden to be pushed right up to the filament screw and the gap to be kept as small as possible.

Push the Teflon Bowden into the heat sink as far as it will go. The Bowden can now be moved by approx. 1 mm.

Push the Teflon Bowden into the heat sink as far as it will go. The Bowden can now be moved by approx. 1 mm.- Lift the Pushfit with a tool or your fingernail. Then push the Bowden in again as far as it will go. It should now no longer be possible to move the Bowden.

- Cut the Bowden so that it protrudes 6 mm from the hotend.

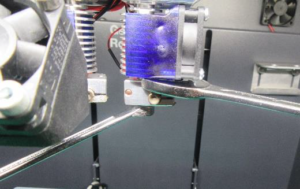

- Insert the hotend into the extruder with slight rotational movements and tighten the clamping screws.

Ensure that the Bowden does not touch the filament screws.

- Reconnect all plug connections.

- Heat the hot end to 285° - 290 °C.

Important! Assembly at lower temperatures leads to sporadically clogged hotends or to parts coming loose during printing! - Tighten the nozzle against the heating block (torque 3 Nm!). Then tighten the heating block against the heat sink (7 mm and 16 mm open-end spanner).