Error description

You have two or more installations of GP Manager and would like to transfer data between them.

Troubleshooting

There are several ways to share data between different installations, depending on the effort involved.

Each method has its own advantages and disadvantages. Which method is suitable for you depends, among other things, on how your company IT is organised.

Export GPF files and import them on the target computer

This method requires some manual work, but also reliably backs up the data. You can use this method to both transfer the data and perform a backup. However, the effort required increases with each additional installation.

This is a particular problem if data is collected on several computers, but needs to be available on all of them. With more than 2-3 installations, the effort involved in this case is considerable.

How to back up and restore GPF files is described here: "How can I back up the data from my GP Manager?„.

Advantages

- If you use this method regularly, you will automatically have a data backup.

- If the data volume is low, you can also send the data as an email.

- With regular backups, only the newly created data needs to be backed up. A single data backup only takes a short time.

Disadvantages

- You could also send individual data records manually by email, but this is quite time-consuming as you have to search for the relevant files using the customer number. As a result, the data is usually only available on the target system after a long delay. Depending on the frequency of the backup Daily, Weekly, ...

- The data must be backed up on each computer on which it is recorded and, if necessary, transferred to all other computers. The effort involved increases with every computer that is added.

Using GP Manager with a server

This method is only available to you if you have also purchased the GP Manager as a server version. If the GP Manager installations can be connected via a network, you can use the method of using one installation as a server. The server manages the database with all measurements and the other GP Manager installations access it.

Advantages

- All GP Manager installations have access to the same data.

- Once measurements have been recorded, they are immediately available to all installations.

- Once set up, this method requires hardly any manual intervention.

- Ideally, only the server needs to be backed up so that all data collected with GeBioM products is backed up (this only applies if all installations are actually used exclusively in server mode).

Disadvantages

- There should be a fast network connection between the individual installations (a local network or a fast Internet connection).

- If the data is transferred via the Internet, a VPN server is also required, as the GP Manager requires Windows shares.

- A computer is required as a server on which the entire system runs.

- If the server fails, the other installations also stop working.

- If no network connection to the server is possible, the other installations will no longer work.

- If no data backup is performed on the server, in the worst case all data will be lost if the server loses data.

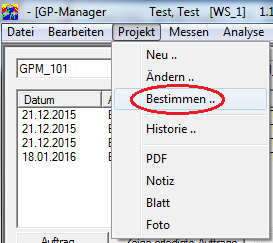

Save and open customers

You can always export individual customers via "File" -> "Save" and then import them in another installation with "File" -> "Open".

Advantages

- The function is activated for every GP Manager installation.

- Easy to use, once a customer has been selected, it can be saved.

- Good control over the data that is shared.

Disadvantages

- If several data records are to be transferred, the method is time-consuming.

- You must transfer the measurements individually.

- Depending on how you transfer the data, the data may not be available on the target computer until later.

- If the data is to be available on several computers, this method is labour-intensive.

Sending data records with GP Mail

You can purchase the GP Mail module, which allows you to send customers emails directly from the GP Manager.

Advantages

- You can select the target installation for each data record you want to send.

- You can control very precisely which data you would like to transfer.

- The data can be made available on the target system in a timely manner, as it can be sent quickly by email.

Disadvantages

- You must transfer the measurements individually.

- This method is only suitable if only a few measurements are to be divided.

- As all customer data is sent in one email, this only works with smaller data sets. Sending videos quickly fails if the email attachment is too large

- The data records must be imported individually on the target computer.

- It is time-consuming to make all measurements available on all installations.

If you need advice on which method is suitable for you or how to configure the GP Manager, you are welcome to call GeBioM Support.