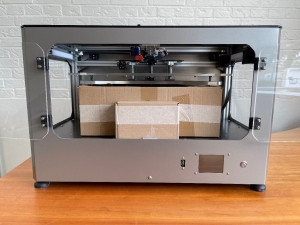

Thermoplastics for 3D printing can lead to the release of ultra-fine particles (UFPs) and volatile organic compounds (VOCs), depending on the thermoplastic used and the settings of the 3D printer. Above certain concentrations (threshold values, TLV), these emissions can pose a risk. The concentrations are influenced by the filament and adhesive used, the printing conditions (e.g. printing temperature), the room volume, the air exchange rate (AER) and the number of printers in a room.

Depending on your specific situation, please observe other safety measures, such as a filter and/or a special ventilation system.

The use of printing materials / filaments from different suppliers may require additional safety measures. Always refer to the relevant information from the supplier of such filaments/materials and the safety data sheet of each specific material.

GeBioM mbH cannot be held responsible for any adverse effects of the use and/or performance of these materials.

Static magnetic field hazard. Due to the static magnetic field caused by the magnets in the printer, keep a distance of at least 4 cm between implanted electronic medical devices and implants that contain ferromagnetic materials.

Static magnetic field hazard. Due to the static magnetic field caused by the magnets in the printer, keep a distance of at least 4 cm between implanted electronic medical devices and implants that contain ferromagnetic materials.