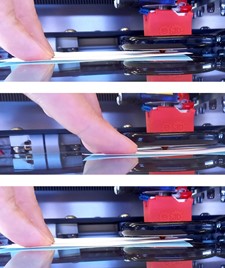

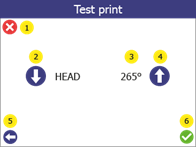

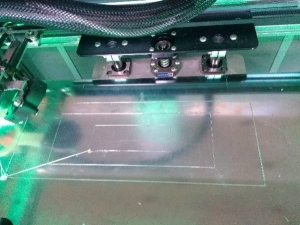

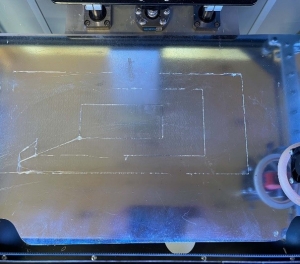

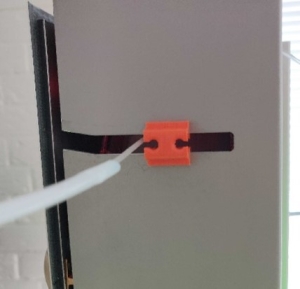

It is an essential requirement of the 3D printing process that the print head is always at a constant distance from the printing surface (print bed) while printing the bottom of the object.

If the distance is too big, the extruded material will not stick to the printing surface and will be dragged around by the head.

If the distance is too small (or the head and bed are touching), material will not come out of the head, which may result in clogging (the material will get stuck inside the head and additional maintenance will be required to bring the printer back in operating conditions)

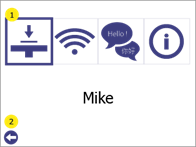

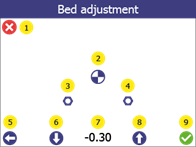

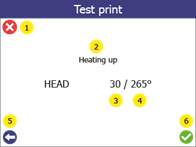

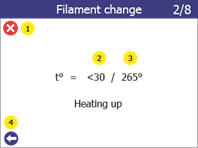

The 3D printer Mike features an algorithm for correcting imperfections in the bed level. However, sometimes the reference height (starting point) parameter is required to be adjusted with the help of the user.